Ever since part 6 of this project, ever since when I fitted and installed a brand new head unit and amp, I've been plagued by a constant, rpm-dependent whine of the alternator in the speakers.

To fix this I have tried every single 'noise isolator' and adapter known to man, I spent probably £300-400 on them.

I have tried different head units, amps, alternators and everything else you can think of and it made no difference to the whine.

Here's an example of the whine:

After trying everything i could think of, i contacted Gordon at AMP Doctor (https://www.ampdoctor.co.uk/) who suggested fitting a 100000uF 25V capacitor between the alternator and the rest of the car, I got straight onto it:

To my amazement, this reduced the whine by about 80% to this:

Of course 80% wasn't enough for me and with the amp gain turned up a bit it was even louder so i continued looking further.

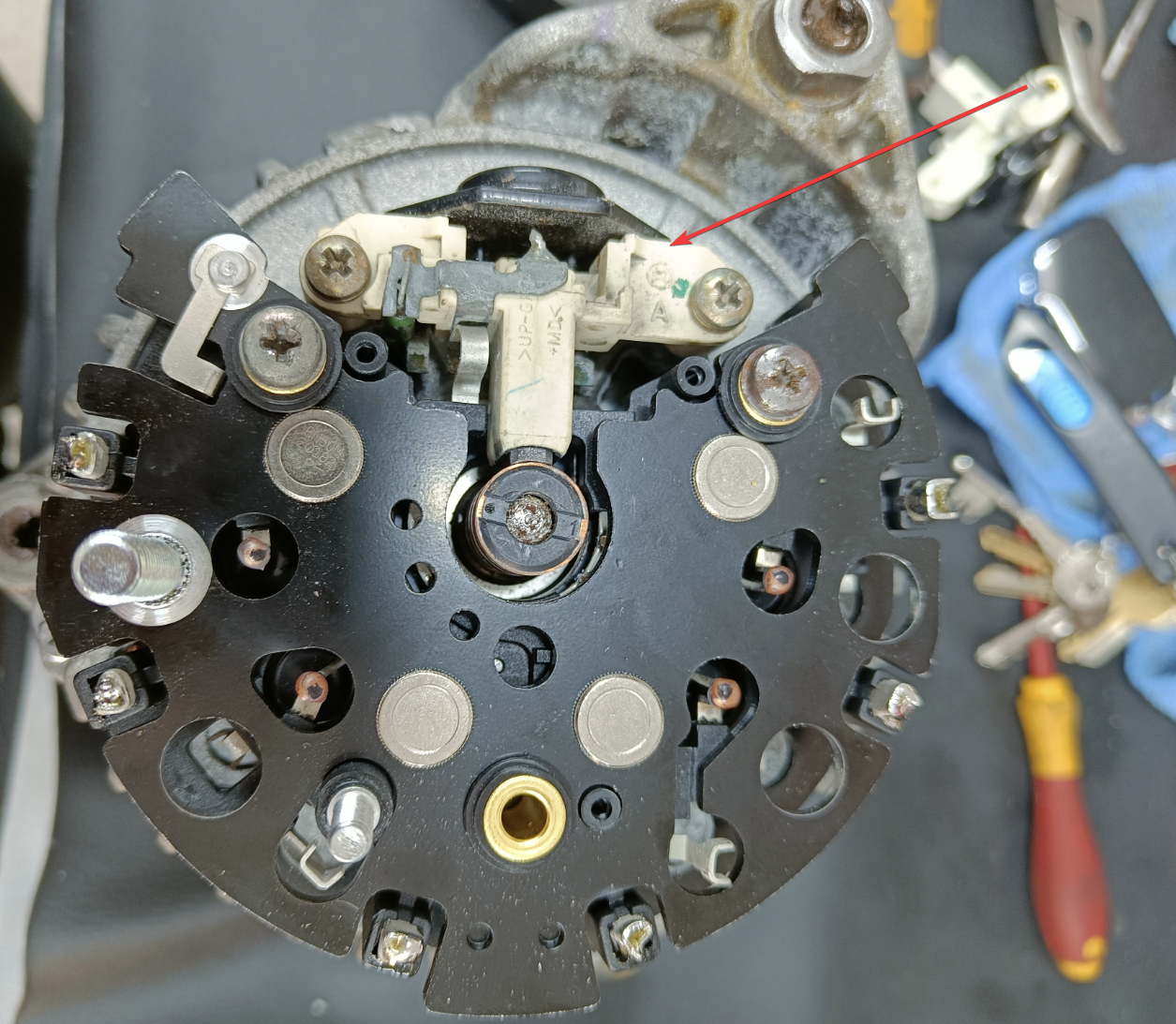

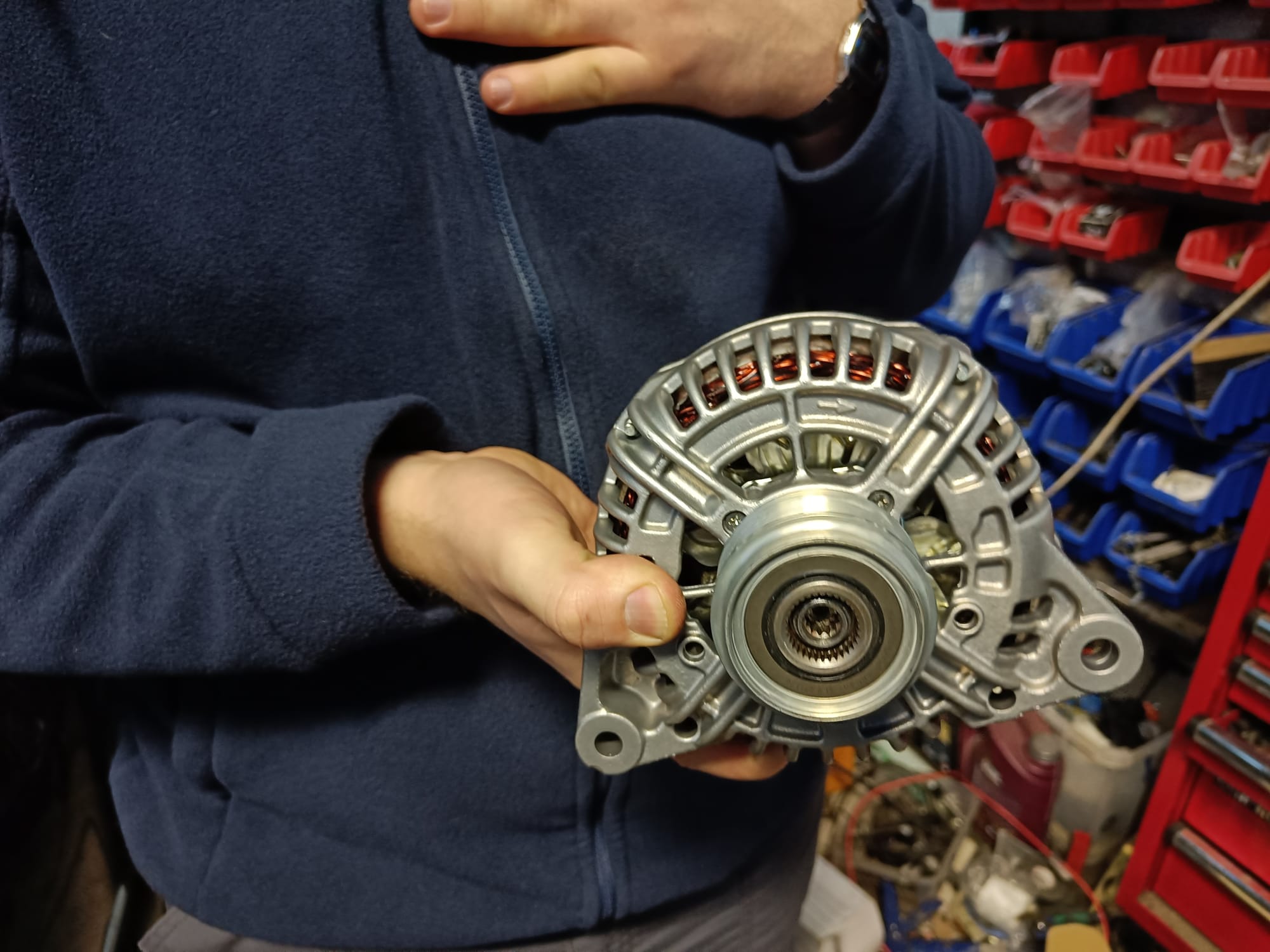

After research i understood that a D2 alternator regulator is a transistor type one like this:

All the newer generation model cars like from 2003 and up have a new generation of alternators with a mosfet style regulator like below, so i thought why not try it.

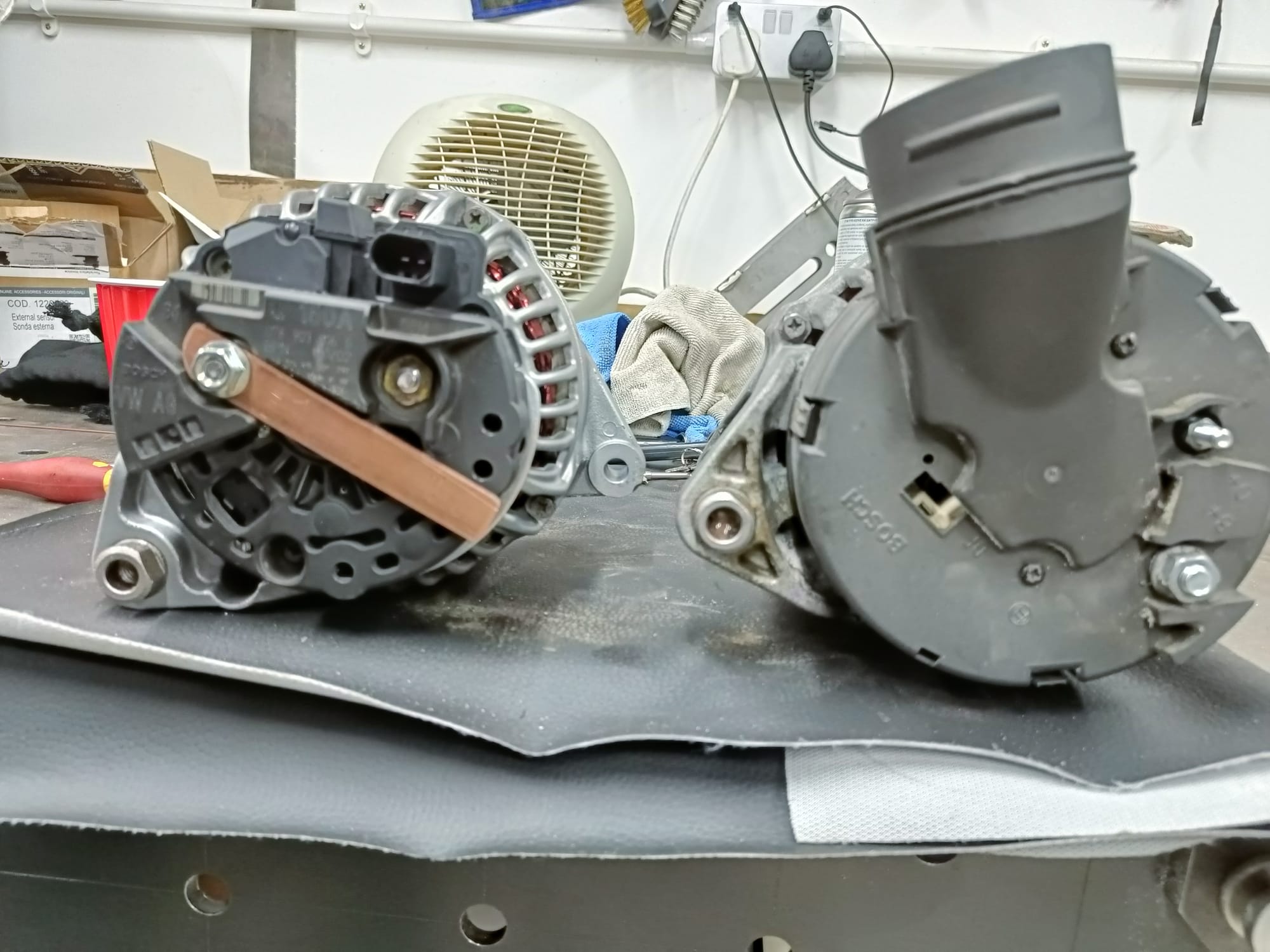

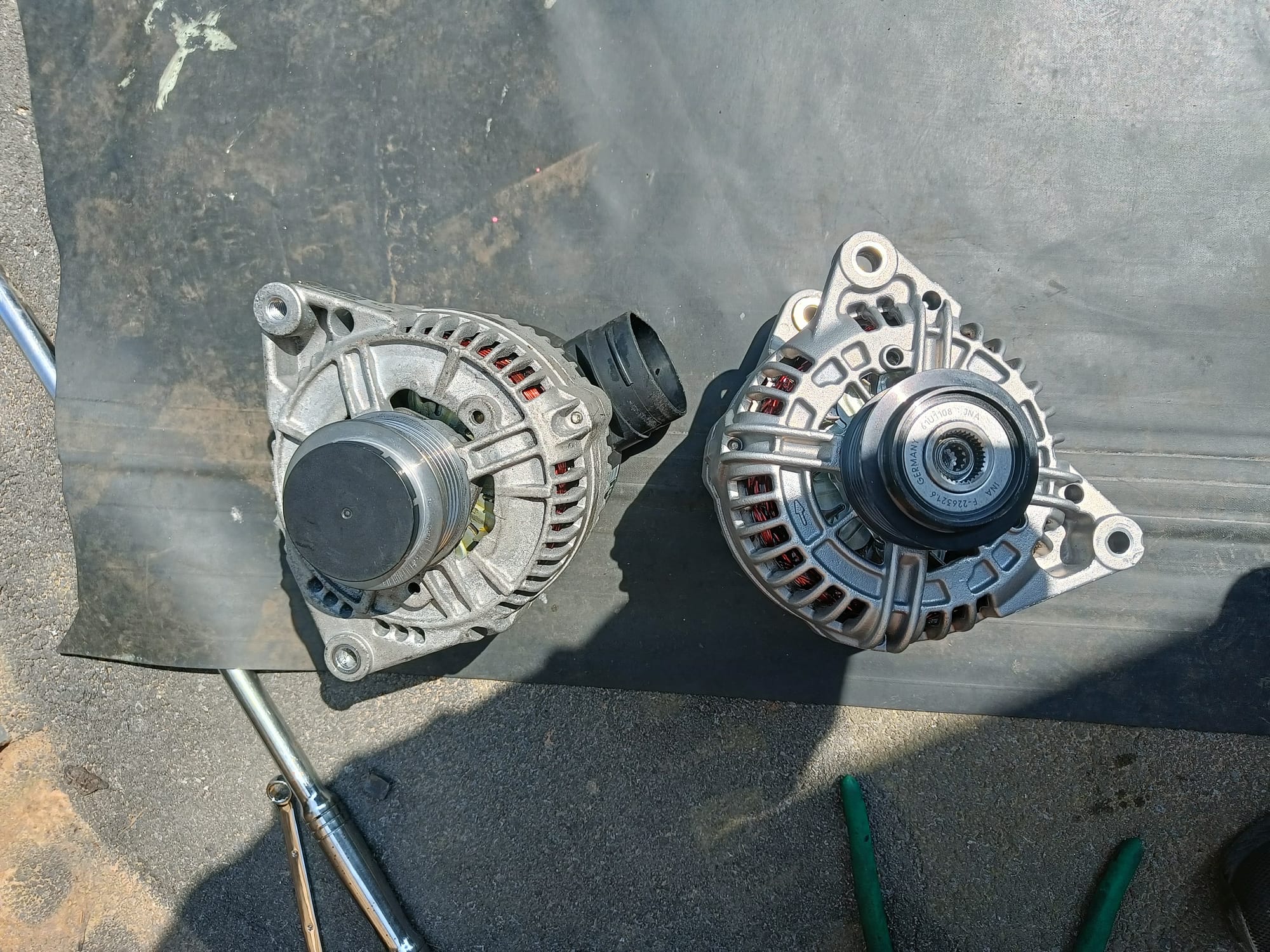

So i started by getting a second hand 'new gen' alternator for £28. It fits V8 and V6 D2's as well. Part number is 078903016S.

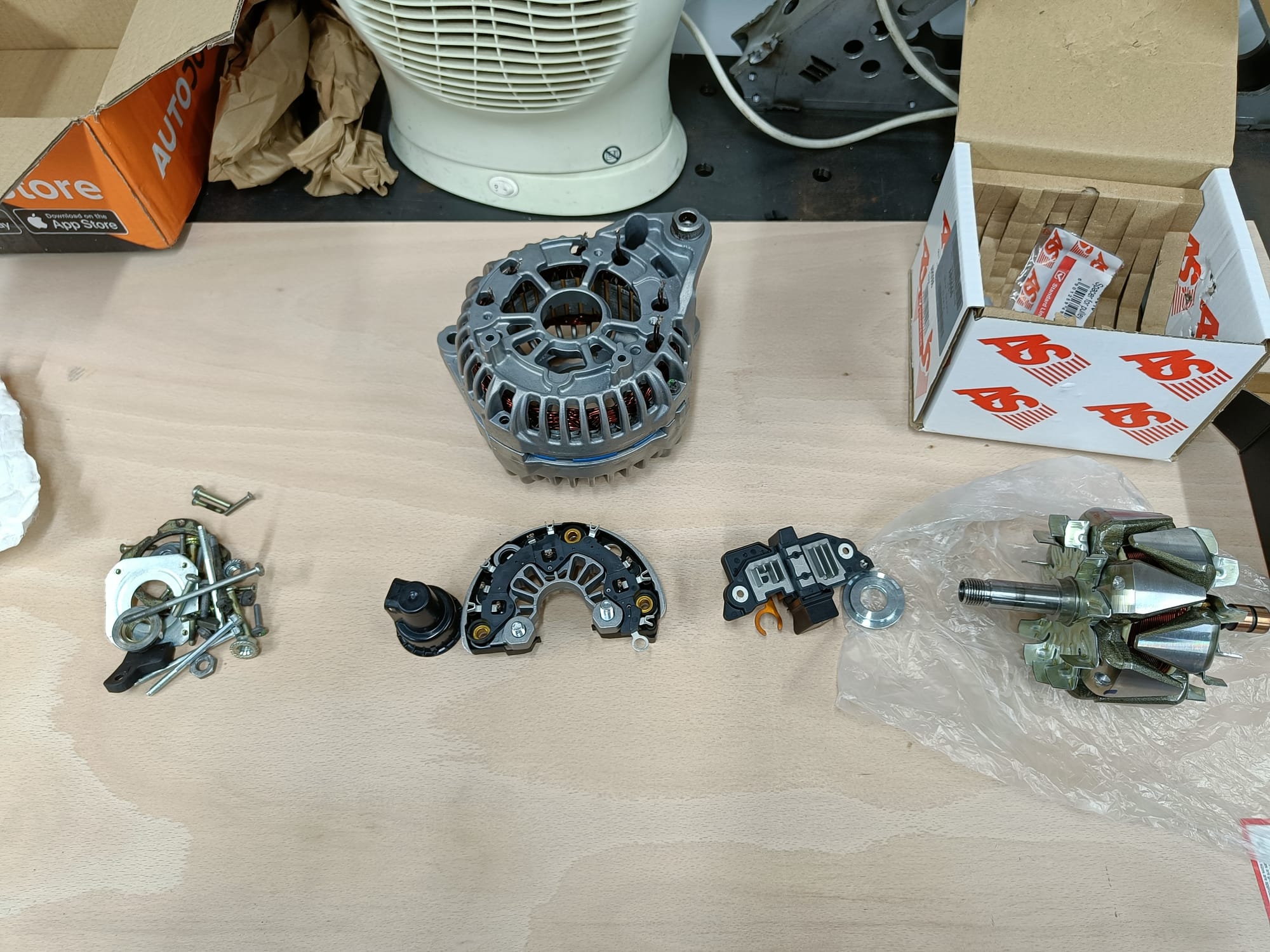

I completely disassembled it and had the casing vapor blasted.

Before:

After:

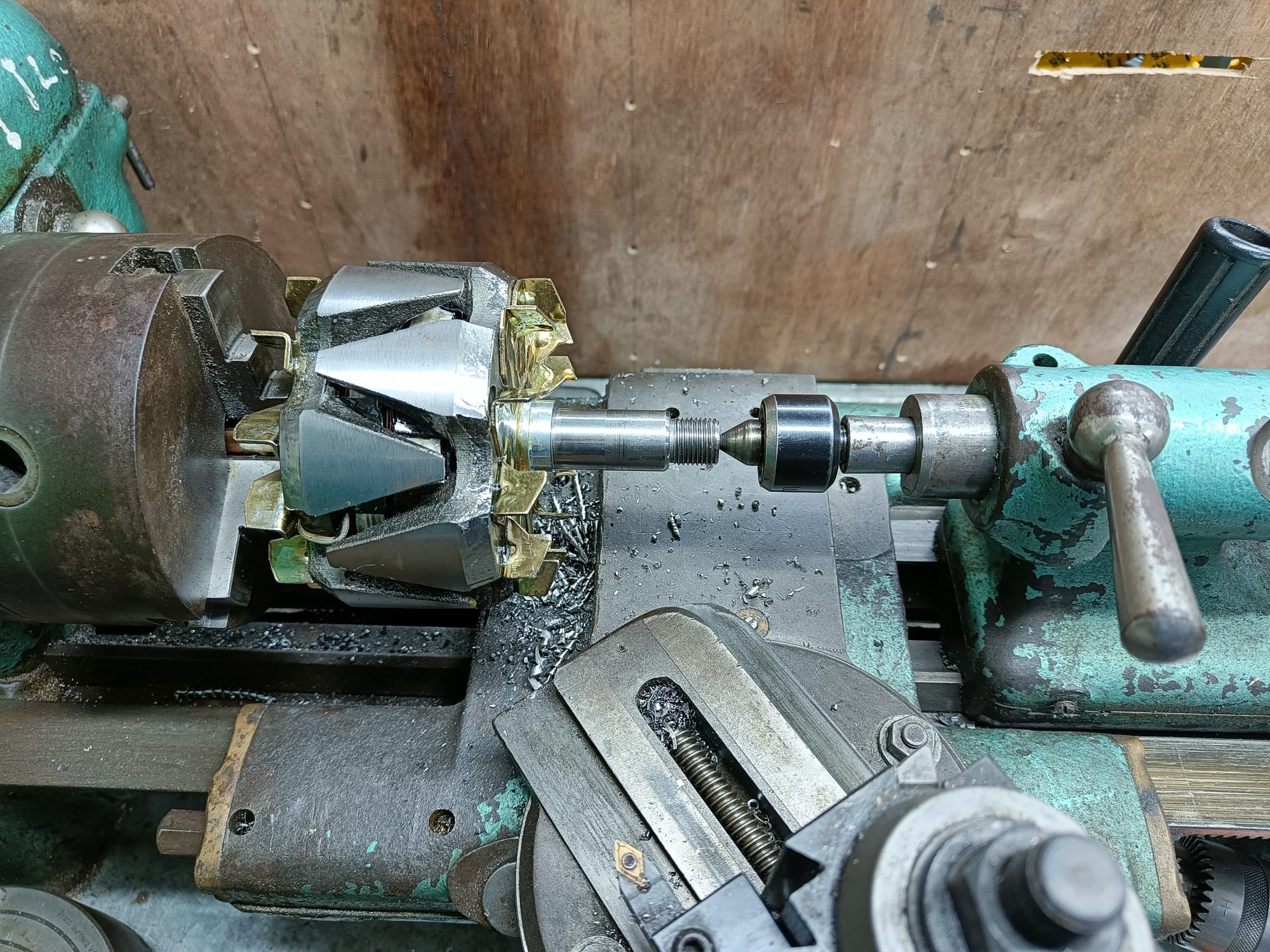

The 2.8 alternator has a longer rotor shaft to accommodate the one way clutch pulley, but the casing of the 'new gen' alternator is shorter, so to accommodate this the shaft of the 2.8 alternator has to be modified - the thread has to be lengthened towards the center:

I used a good friend in Devon with a lathe:

Components ready for assembly:

New bearings:

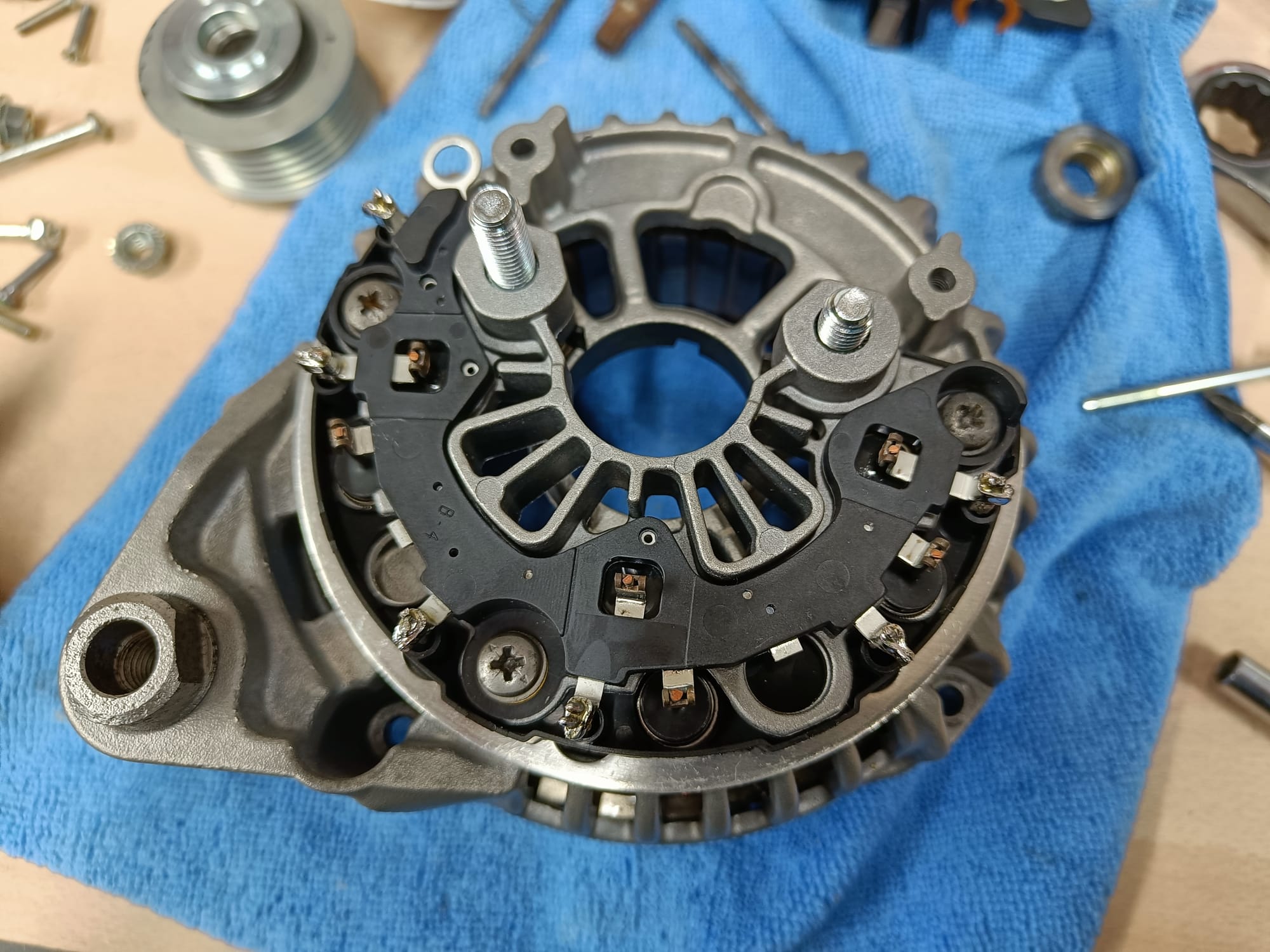

Rectifier being soldered onto the the winding and casing:

The rear positive terminal connection is in a different place on the new gen alternator compared to D2, so i made a bus bar:

Once i knew the dimensions were ok i 3D printed a custom support for it:

I also managed to find a brand new NOS freewheel pulley from INA:

Checking the runout:

And the alternator was ready for fitting:

The result? 100% clean audio with no alternator whine.

If any V8 owners are reading this, you just need the 078903016S alternator and the pulley from your original alternator, the pulley bore has to be shortened by about 8mm so that the nut fits on and you have to make a bus bar like I did.

One annoying thing i also experienced was a wandering belt on the tensioner pulley:

Replacement of the alternator and tensioner pulley didn't help, so i replaced the continental belt with a Dayco, which was of completely different material and the movement stopped:

Part 8: